Home Page

About Us

Letter From the Founder

I wanted to take a moment to say thank you for your interest in our quality woodworking machines. Here are Woodtech Machinery, LLC, we take pride in what we do. Our daily goal is to bring quality woodworking machines to the market, and offer them at a fair and affordable price. Couple that with attentive service, and we feel like we have found a winning combination.

Machinery and woodworking has been in our family for years. My father ran a machine shop for over 40 years building machinery for sawmills and woodworking manufacturing facilities. I personally started and operated a successful wood products company for 14 years. I say that to bring to light the fact that not only are we familiar with machinery, we have also operated these types of machines as a manufacturer over the years. This experience has significantly informed our process in manufacturing quality machines. These machines are products we would be proud of to have in our own manufacturing business.Benjamin Franklin once said – Well done is better than well said. I can sit here at my desk all day, and this paper I'm writing this on will allow me to write anything that I want, But in the end, I would rather humbly ask that you give us the opportunity to work for you, and show you how we can help you with your machinery needs.

From our family to yours!

We wish you many blessings!

Optimizing Saw

Optimizing Saw WTM-CS20x

Wood Dimensions:

Ingoing lengths min./max. 800mm – unlimited

Ingoing widths min./max. 50 – 300mm

Ingoing thicknesses min./max.2 – 12mm

Cross sections max. 300x5mmm max. 150x80mm

Cutting tolerance: +/- 0.5 – +/- 1.5mmCapacity:

Saw cycle: 1-6 times per second (servo drive)

Feed speed infinitely adjustable: 0-120 m/min.

Machine working height: 35”Electrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

Full electrical load: 20.5 kW

Operating load: 8 kW

Operating voltage: 460 Volt/60Hz/3

PhaseAir consumption: approx. 1200 L/min.

Service pressure: approx. 30m/sec

Diameter of dust exhaust ducts: 120mm (2pcs)Automatic Finger Jointer Line

Model:

WTM-1560x600IIGModel Name:

Automatic Finger Jointer lineMF756A Infeed strap conveyor:

Working table Length: 1150mm

working table width: 600mm Motor power: 0.375kwMXZ3515-II Auto finger shaper:

Table size: 850W x 600L mm

Max. working size: 850L x 80W x 150H mm

Min. working size: 200L x 30W x 20H mm

Shaper spindle diameter: 70mm

Shaper blade diameter: 160mm

Main saw blade size: 255mm

Shaper spindle speed: 5000 rpm

Main saw spindle speed: 2840 rpm

Working air pressure: 0.8

Mpa Total power: 16.12kwMF756B Middle strap conveyor:

Working table Length:1150mm

working table width: 600mm

Motor power: 0.375kwMXZ3515T-II Auto finger shaper(glue-spreading):

Table size(W x L): 850 x 600 mm

Max. working size(L x W x H): 850 x 80 x 150mm

Min. working size: 200L x 30W x 20H mm

Shaper spindle diameter: 70mm

Shaper blade diameter: 160mm

Main saw blade size: 255mm

Shaper spindle speed: 5000 rpm

Main saw spindle speed: 2840 rpm

Working air pressure: 0.8 Mpa

Total power:18.74kwMF746 Roller output conveyor,

MF761 Chain conveyor@2sets

(Include 1 set Tipper)MHZ 1560 Auto finger joint assembler:

Max. working size: 6000L x 150W x 80H mm

(1times can make 2 workpiece)

Min. working size: 1500L x 30W x 20H mm

Main saw blade size: 355mm

Working air pressure: 0.8 Mpa Max.

Jointing force: 7800kg

Total power: 8.45kwGang Rip Saw

Model Name: Movable Gang Rip Saw

Model:

WTM-RIP350Specification:

1. Max. cutting width: 350mm

2. Max cutting thickness: 10-100mm

3. Min. working length: 750mm

4. Number of saw blade: Movable 3 blades

5. Saw blade dia.: 300-400mm

6. Spindle rotation speed: 4200 rpm

7. Blade adjustment speed: 44-66 m/sec

8. Feeding motor speed: 6-48m/min

9. Number of saw blades: 6 blades

10. Saw spindle dia.: 65mm

11. Number of pressure rollers: 4

12. Electronic lasers for each bladeElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseStraight Line Rip Saw

Model: WTM-SLR460

Model Name: Straight line rip saw

Specification:

Working Thickness: 10-90mm

Min. Working Length: 200mm

Max. Working Width: 460mm

Main Motor Power: 11kw

Feeding Motor Power: 1.5kw

Elevation Motor Power: 0.25kw

Total Motor Power: 12.75kw

Feeding Speed: 10-33m/min

Spindle Speed: 2900 rpm

Saw Blade Dia.: 350-400mmElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseModel: WTM-SLR660

Model Name:

Straight line rip sawSpecification:

Working Thickness: 10-90mm

Min. Working Length: 260mm

Max. Working Width: 660mm

Main Motor Power: 15kw

Feeding Motor Power: 2.2kw

Elevation Motor Power: 0.25kw

Total Motor Power: 17.45kw

Feeding Speed: 10-33m/min

Spindle Speed: 3000 rpm

Saw Blade Dia.: 400-450mmElectrical Requirements:

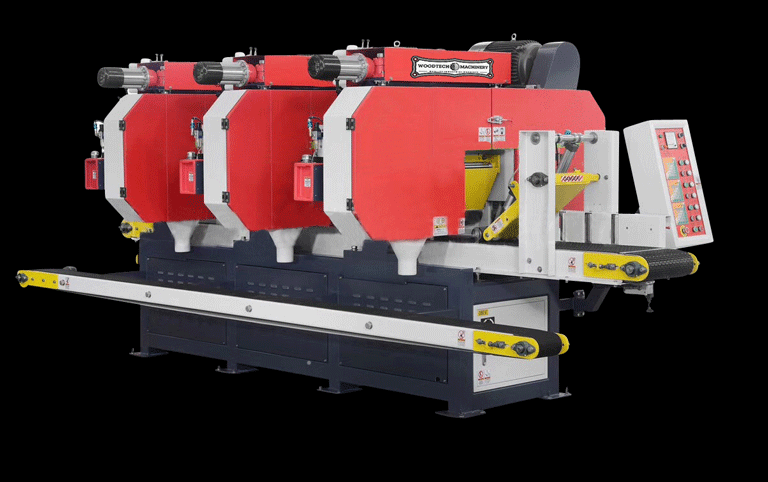

Operating voltage: 460 Volt/60Hz/3 PhaseHorizontal Band Saws

Model:

WTM-400Z2 and WTM-400Z3Model Name:

Two or Three heads HD Horizontal Band Saw

Max. workpiece size: 300mm

Thickness of production board: 5-130mm

Width of conveyor belt: 375mm

Diameter of saw roller: 711mm

Diameter of saw wheel: 711mm

Feeding speed: 0-15m/min

Hydraulic pressure: 50-60kg/cm

Size of saw blade: 185”

Length, 2” wide, 1.6mm thickElectrical Requirements:

Voltage: 460V/60 HZ/3 phase

Full electrical load: 18.5 KW x 2 or 3 depending on the model

Approx Overall dimension: 2800L x 2200W x 2000HHorizontal Band Saw

Model:

WTM-400ZModel Name:

HD Horizontal Band Saw

Max. workpiece size: 300mm

Thickness of production board: 5–160mm

Width of conveyor belt: 375mm

Diameter of saw wheel: 711mm

Feeding speed: 0-15m/min

Hydraulic pressure: 50-60kg/cm

Size of saw blade: 185”

Length, 2” wide, 1.6mm thickElectrical Requirements:

Voltage: 460V/60 HZ/3 phase

Full electrical load: 18.5 KW

Overall dimension: 2800L x 2200W x 2000H

Panel Saws

Multi-Blades Panel Saw line

Model:

WTM-1600Multi-Blades Panel Saw:

Main Spindle Dia: 74mmSaw

Blade Diameter: 205mmMax. Working Width:

1600mm Working Thickness: 0-30mm

Main Spindle speed: 2600rpm

Feeding Speed:0-15m/min

Main Motor Power: 22kw

Feeding Motor Power: 1.5kw

Min. Raw Panel Width: 650mm

Rubber Roller: 12pcsAnti-kickback safeguardElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3

Phase Options:

Semi-automatic hydraulic lifting and receiving table:

Max Weight Loading:3000kgs

Lift Table Size: 1600 X 2400mmAutomatic pusher machine (including CNC lift table):

Automatic push plate stroke: 3000mm

Push plate thickness: 8-100mm

Push speed: 0-25m/min

Frequency conversion motor power:0.75kw

Table Size: 1600*2400 Max Weight Loading: 3000kgs

Feeding Motor Power:3kw

System: Delta PLC control connect Pusher and lift table