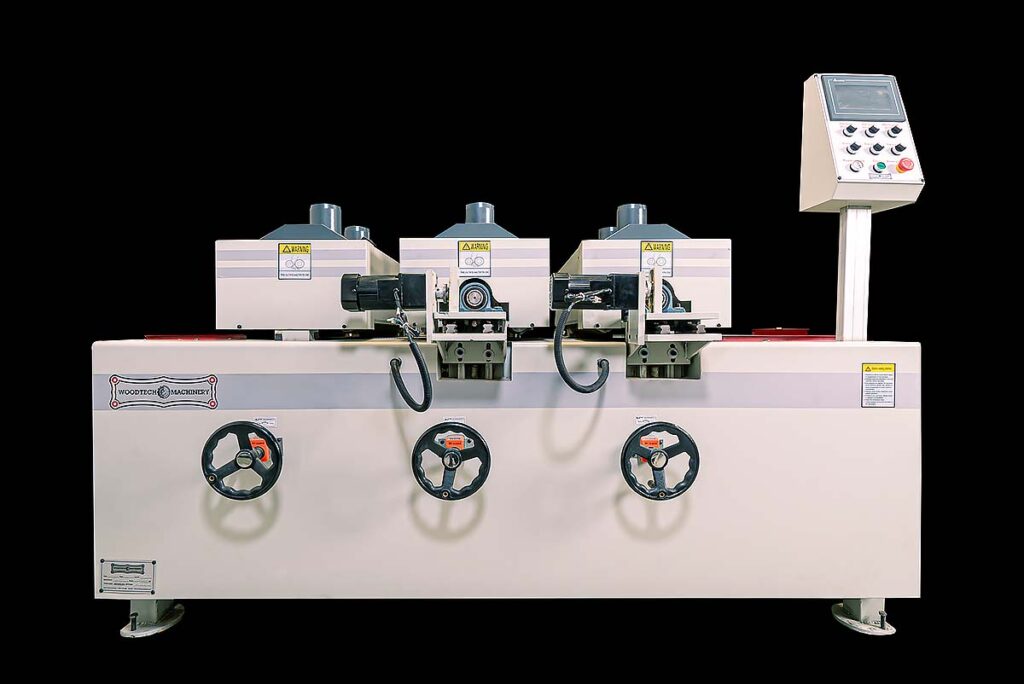

Denibbing Machine

Model: WTM-UVDB Series

Model Name:

Denibbing/sanding machine. This machine is for denibbing/sanding of wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in 2-6 head configurations

5. Working height: 800mmFeatures:

1. Feed belt thickness 5mm, high temperature resistance fish bone belt.

2. Schneider Electronics

3. Delta frequency converter control each brushing heads individually

4. Adjustable height pressure roller- 2 rolls per head

5. Height counters with individual height adjustment

6. Multiple sanding grits, and brush lengths available

Optional – Precision automatic lifting motor for height adjustmentElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

In-Line Finish Sander

Model: WTM-UVS Series

Model Name:

In-line finish sanding machineApplication:

Sanding for PU, UV, PE finishesSpecification:

1. Available in 24”, 36”, 51” Widths

2. Workpiece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in single or double head configuration

5. Working height: 800mm

7. Conveyor belt thickness- 5mm

8. Sanding belt size: 60” Length

9. Schneider electronics

10. Variable speed on sanding heads

11. Cleaning brush on the output sideElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseWire Brushing/Denibbing Machine

Model: WTM-UVWB Series

Model Name:

Wire brushing/ Denibbing Sanding MachineApplication:

Wire brushing, embossment, texturing, of the grain in wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Min working length: 300mm

4. Feeding speed: 5-20m/min

5. Available in 2-6 head configurationsFeatures:

1. Feed belt thickness 5mm, high temperature resistance fish bone belt.

2. Schneider Electronics

3. Delta frequency converter control each brushing heads individually

4. Adjustable height pressure roller- 2 rolls per head

5. Height counters with individual height adjustment

6. Multiple wire diameter and bristle lengths available

* Optional -Precision automatic lifting motor for height adjustmentElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseSingle Head Roll Coater

Model Name: Roll Coater

Model: WTM-UVRC series

Application:

Roll coating for finish on wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Min working length: 300mm

4. Feeding speed: 5-20m/min

5. Available in single head configuration

6. Working height: 800mmFeature:

1. Italian JMC Aluminum alloy reduction gear drive.

2. Schneider electronics

3. High-quality coupling transmission. NSK Japanese bearings.

4. Conveyor belt is a 2MM anti-sliding PVC conveyor belt

5. Precision automatic 0.75kw lifting motor for height adjustment

6. All adjustments are fittied with individual counters

7. Rubber or sponge heads available per customers needElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseGrain Filling Machine

Model: WTM-UVGF Series

Application:

Reverse roll coating for grain fill on wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Min working length: 300mm

4. Feeding speed: 5-20m/min

5. Available in single or double head configurationFeature:

1. Italian JMC Aluminum alloy reduction gear drive.

2. Filler scrape wheel equipped with RV reducer to control scraper uniformity.

3. Schneider electronics

4. High-quality coupling transmission. NSK Japanese bearings.

5. Conveyor belt is a 2MM anti-sliding PVC conveyor belt

6. Precision automatic lifting motor for height adjustment

7. All adjustments are fittied with individual countersElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseUV Light Dryer

Model: WTM-UVDRYER- Series

Model Name:

UV dryerSpecifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in 2, 3 or 4 light configurations

5. Working height: 800mm

6. Automatic exhaust fans

7. Gallium and Mercery bulbs

8. Schneider Electronics

9. Conveyor is a stainless steel netElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

Double Head Roll Coater

Double Head Roll Coater Specifications

Application:

Roll coating for finish or stain on wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Min working length: 300mm

4. Feeding speed: 5-20m/min

5. Available in double, or triple head configuration

6. Working height: 800mmFeatures:

1. Italian JMC Aluminum alloy reduction gear drive.

2. Schneider electronics

3. High-quality coupling transmission. NSK Japanese bearings.

4. Conveyor belt is a 3MM anti-sliding PVC conveyor belt

5. Precision automatic 0.75kw lifting motor for height adjustment

6. All adjustments are fitted with individual counters

7. Rubber or sponge heads available per customers need

Optional – Double pumps and drains available for individual head use.

Electrical RequirementsOperating voltage: 460 Volt/60Hz/3 Phase