The Woodtech Difference!

Thank-you for your interest in our quality woodworking machines here at WoodTech Machinery, LLC! A couple points that we would like to bring to your attention! Over the last decade, we have seen a lack of quality woodworking machines available in the market. In an effort to bridge the gap of heavy duty machines, and competitive pricing. Our overseas partnerships enable us to manufacture heavy duty, quality machinery at prices that are affordable.

These machines are built to our specifications, with quality parts that are readily available here in the USA. We have a team of technicians that can service the machines on short notice, and have parts on the shelf ready-to-ship for any issues that may arise.

We provide Plant Layout Consultation, Field Service, and Competitive Financing, to make your next equipment purchase as easy as possible. As a family of lifelong woodworkers, we are proud to offer these quality machines for your production facility.

Please contact us today regarding your woodworking equipment needs.

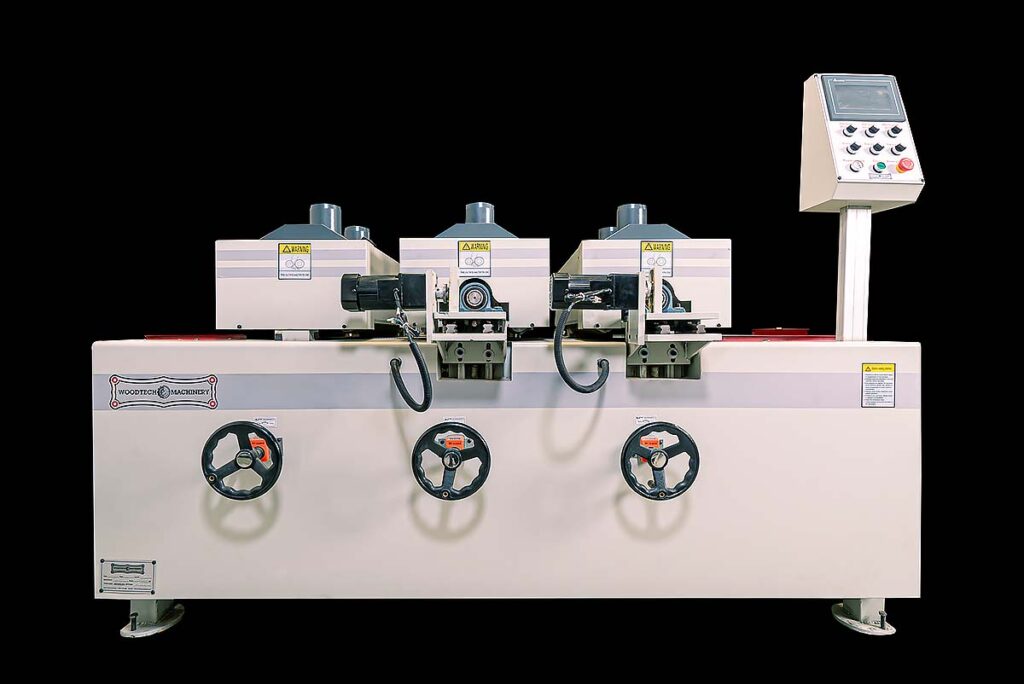

Gang Rip Saw

Model Name: Movable Gang Rip Saw

Model:

WTM-RIP350Specification:

1. Max. cutting width: 350mm

2. Max cutting thickness: 10-100mm

3. Min. working length: 750mm

4. Number of saw blade: Movable 3 blades

5. Saw blade dia.: 300-400mm

6. Spindle rotation speed: 4200 rpm

7. Blade adjustment speed: 44-66 m/sec

8. Feeding motor speed: 6-48m/min

9. Number of saw blades: 6 blades

10. Saw spindle dia.: 65mm

11. Number of pressure rollers: 4

12. Electronic lasers for each bladeElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseStraight Line Rip Saw

Model: WTM-SLR460

Model Name: Straight line rip saw

Specification:

Working Thickness: 10-90mm

Min. Working Length: 200mm

Max. Working Width: 460mm

Main Motor Power: 11kw

Feeding Motor Power: 1.5kw

Elevation Motor Power: 0.25kw

Total Motor Power: 12.75kw

Feeding Speed: 10-33m/min

Spindle Speed: 2900 rpm

Saw Blade Dia.: 350-400mmElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseModel: WTM-SLR660

Model Name:

Straight line rip sawSpecification:

Working Thickness: 10-90mm

Min. Working Length: 260mm

Max. Working Width: 660mm

Main Motor Power: 15kw

Feeding Motor Power: 2.2kw

Elevation Motor Power: 0.25kw

Total Motor Power: 17.45kw

Feeding Speed: 10-33m/min

Spindle Speed: 3000 rpm

Saw Blade Dia.: 400-450mmElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseDenibbing Machine

Model: WTM-UVDB Series

Model Name:

Denibbing/sanding machine. This machine is for denibbing/sanding of wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in 2-6 head configurations

5. Working height: 800mmFeatures:

1. Feed belt thickness 5mm, high temperature resistance fish bone belt.

2. Schneider Electronics

3. Delta frequency converter control each brushing heads individually

4. Adjustable height pressure roller- 2 rolls per head

5. Height counters with individual height adjustment

6. Multiple sanding grits, and brush lengths available

Optional – Precision automatic lifting motor for height adjustmentElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

In-Line Finish Sander

Model: WTM-UVS Series

Model Name:

In-line finish sanding machineApplication:

Sanding for PU, UV, PE finishesSpecification:

1. Available in 24”, 36”, 51” Widths

2. Workpiece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in single or double head configuration

5. Working height: 800mm

7. Conveyor belt thickness- 5mm

8. Sanding belt size: 60” Length

9. Schneider electronics

10. Variable speed on sanding heads

11. Cleaning brush on the output sideElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseWire Brushing/Denibbing Machine

Model: WTM-UVWB Series

Model Name:

Wire brushing/ Denibbing Sanding MachineApplication:

Wire brushing, embossment, texturing, of the grain in wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Min working length: 300mm

4. Feeding speed: 5-20m/min

5. Available in 2-6 head configurationsFeatures:

1. Feed belt thickness 5mm, high temperature resistance fish bone belt.

2. Schneider Electronics

3. Delta frequency converter control each brushing heads individually

4. Adjustable height pressure roller- 2 rolls per head

5. Height counters with individual height adjustment

6. Multiple wire diameter and bristle lengths available

* Optional -Precision automatic lifting motor for height adjustmentElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseSingle Head Roll Coater

Model Name: Roll Coater

Model: WTM-UVRC series

Application:

Roll coating for finish on wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Min working length: 300mm

4. Feeding speed: 5-20m/min

5. Available in single head configuration

6. Working height: 800mmFeature:

1. Italian JMC Aluminum alloy reduction gear drive.

2. Schneider electronics

3. High-quality coupling transmission. NSK Japanese bearings.

4. Conveyor belt is a 2MM anti-sliding PVC conveyor belt

5. Precision automatic 0.75kw lifting motor for height adjustment

6. All adjustments are fittied with individual counters

7. Rubber or sponge heads available per customers needElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseGrain Filling Machine

Model: WTM-UVGF Series

Application:

Reverse roll coating for grain fill on wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Min working length: 300mm

4. Feeding speed: 5-20m/min

5. Available in single or double head configurationFeature:

1. Italian JMC Aluminum alloy reduction gear drive.

2. Filler scrape wheel equipped with RV reducer to control scraper uniformity.

3. Schneider electronics

4. High-quality coupling transmission. NSK Japanese bearings.

5. Conveyor belt is a 2MM anti-sliding PVC conveyor belt

6. Precision automatic lifting motor for height adjustment

7. All adjustments are fittied with individual countersElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseAirjet/IR Tunnel

Airjet/IR Leveling Tunnel

Used for drying and leveling of waterbased and reactive finishesModel: WTM-UVIR series

Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in 24', 36' and 48' lengths

5. Working height: 800mmFeatures:

1. Conveyor is a stainless steel net

2. Heating using far-infrared ray IR ceramic 0.3kw lamp tube and 30kw heating box.

3. Temperature control adopts independent control, accurately control the temperature. The side cover of the oven is easy to be disassembled and installed convenient for maintenance.

4. Side covers open for convenient lamp disassembly or maintenance.

5. 5.5KW high pressure fan, sprayed and dried by 38 jet tipElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseStain Brushing Machine

Model: WTM-UVBR Series

Model Name:

Stain Brushing MachineApplication:

Specially designed for brushing stain or other finishes on wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in 2,3 or 4 head configurations

5. Working height: 800mmFeature:

1. Flat anti-slip solvent resistance belt, belt thickness: 2mm thickness

2. Driving motor 1.5kw Schneider Inverter control

3. The brush heads slide out for easy cleaning.

4. Variable speed drives on each brush.Electrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase