Transfer Conveyor

Automatic Transfer Conveyor

Model:

WTM-UVC SeriesSpecifications:

1. Available in 24”, 36”, 51” Widths

2. Workpiece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in 6', 8', 10' lengths

5. Working height: 800mm

6. Total power: 0.75kwFeature:

1. Flat anti-slip solvent resistance belt, belt thickness: 2mm thickness

2. Conveyor use 0.75kw Taiwan RV63/30 reduction gears

3. Schneider Frequency converter controls belt speedElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseUV Light Dryer

Model: WTM-UVDRYER- Series

Model Name:

UV dryerSpecifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in 2, 3 or 4 light configurations

5. Working height: 800mm

6. Automatic exhaust fans

7. Gallium and Mercery bulbs

8. Schneider Electronics

9. Conveyor is a stainless steel netElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

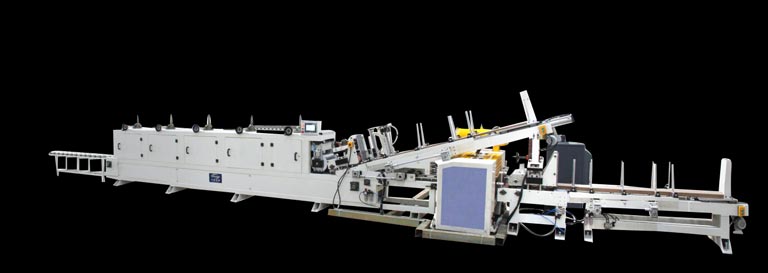

Double Head Roll Coater

Double Head Roll Coater Specifications

Model: WTM-UVRCD series

Application:

Roll coating for finish or stain on wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Min working length: 300mm

4. Feeding speed: 5-20m/min

5. Available in double, or triple head configuration

6. Working height: 800mmFeatures:

1. Italian JMC Aluminum alloy reduction gear drive.

2. Schneider electronics

3. High-quality coupling transmission. NSK Japanese bearings.

4. Conveyor belt is a 3MM anti-sliding PVC conveyor belt

5. Precision automatic 0.75kw lifting motor for height adjustment

6. All adjustments are fitted with individual counters

7. Rubber or sponge heads available per customers need

Optional – Double pumps and drains available for individual head use.

Electrical RequirementsOperating voltage: 460 Volt/60Hz/3 Phase

Linear Spray line

Automatic Profile Spraying Machine

Model:

WTM-SP400Specification:

Processing width: 10-400mm

Processing thickness: 10-100mm

Min. length: 400mm

Feeding speed: 0-50m/min

Spraying guns: 6 Working pressure: 0.5-0.8Mpa

Total power: 2.25KwElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseReciprocal Spray Line

Automatic Reciprocal Spraying Machine

Model:

WTM-SP2500Specifications:

Max. working width: 1300mm

Max. working length: 2440mm

Max.spraying thickness: 150mmSpraying guns: 8

Working pressure: 06-0.8Mpa

Total power: 10.85kwElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhasePUR Glue Line

PUR Glue Melter

Model:

WTM-PUR-120Specifications:

27kg/hour Application guns: 2

Size: 560x340x635mm

Main power: 7.8kwElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3

Motor rorating: 0.5-60/minPUR Glue Line

PUR Automatic Floor Laminating Line

Model – WTM-PUR-350

Specifications:

Working width: 100–350mm

Plywood thickness: 9-18mm

Feed Speed: 5-15m/minAir consumption: 0.1 CBM/min

Approx overall Dimensions: 17.4L x 1.6W × 1.4HElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

Glue Spreader:

Silicon Rubber Roller: 0.75KW X 2

Lifting motor: 0.37KW

Dosing Roller: 0.37KW

Heating Power: 3KW X 2 (Oil heating)

Coating Roller: 240×500

SiliconDosing roller: 216×500

Chrome Electrical thickness adjustment

Manual glue thickness control

Pinch Roll: Chain Drive Drive Power: 4kw Manual thickness control

Pneumatic pressure, 4 sections

First section pressing rolls: rubber with 40 Durometer

2-3 -4 sections pressing rolls: AluminumDouble End Tenoner

Heavy Duty 4 sided Moulder

Heavy Duty Double end Tenoner

Model:

WTM-D80Specifications:

8 Spindles – multiple configurations

Working Thickness – 10mm-120mm

Working Width – 250mm-2500mmElectrical Requirements:

Full electrical load: 44kW

Operating voltage: 460 Volt/60Hz/3 Phase

* ask for additional detailsThe Woodtech Difference!

Thank-you for your interest in our quality woodworking machines here at WoodTech Machinery, LLC! A couple points that we would like to bring to your attention! Over the last decade, we have seen a lack of quality woodworking machines available in the market. In an effort to bridge the gap of heavy duty machines, and competitive pricing. Our overseas partnerships enable us to manufacture heavy duty, quality machinery at prices that are affordable.

These machines are built to our specifications, with quality parts that are readily available here in the USA. We have a team of technicians that can service the machines on short notice, and have parts on the shelf ready-to-ship for any issues that may arise.

We provide Plant Layout Consultation, Field Service, and Competitive Financing, to make your next equipment purchase as easy as possible. As a family of lifelong woodworkers, we are proud to offer these quality machines for your production facility.

Please contact us today regarding your woodworking equipment needs.